Our 21-Step Reconditioning Process

You Get The Best From Typewriters.com

Experience Unparalleled Quality with Typewriters.com

At Typewriters.com, we're not just selling typewriters; we're delivering a legacy of precision engineering and timeless value. Our meticulous 21-Step Reconditioning Process is a testament to our unwavering commitment to excellence. With over half a century of expertise, our service technicians, seasoned in the intricacies of typewriter craftsmanship, ensure that each reconditioned unit you receive is unmatched in quality.

Our Promise: Reliability in Every Keystroke

We understand the nuances of the IBM models and a spectrum of classic typewriters, enabling us to provide you with a machine that doesn’t just work but works wonders for you. When you choose Typewriters.com, you're not just purchasing a typewriter; you're securing a reliable partner for every word you type.

Connect with Typewriters.com Experts

We welcome you to call us at (404) 377-1884, contact us through our live chat, or email us at info@typewriters.com and a member of our team will be happy to assist you with selecting the right typewriter for your needs.

Dive into the Details: Our Comprehensive 21-Step Reconditioning Process

- Thorough Cleaning: Each machine is disassembled, and every component is meticulously cleaned.

- Rigorous Inspection: We examine each part for wear and tear, ensuring only the best quality.

- Precision Reconditioning: Print hammer solenoids are renewed, and we install fresh caps for flawless performance.

- Rubber Rejuvenation: All rubber parts are treated to extend their life and performance.

- Platen Resurfacing: We ensure the platen is impeccable for clear, consistent printing.

- Gear Renewal: New steel gears are installed in Series I transport motors for superior durability.

- Connectivity Check: Keyboard and circuit board connectors are tested for secure connections.

- Battery Box Inspection: Any sign of corrosion leads to a replacement to guarantee reliability.

- Platen Latch Examination: We ensure platen latches are secure for steady paper feeding.

- Factory-Spec Lubrication: Machines are reassembled with precision lubrication to meet original factory specifications.

- Ground Strap Verification: We check all grounding for electrical safety and functionality.

- Adjustment Assurance: All factory settings are verified for optimal performance.

- Printwheel Perfection: Each character is tested multiple times to ensure flawless printing.

- Mechanical Integrity: The machine undergoes a thorough check for gear and tabulation accuracy.

- Paper Insert Testing: SAPI functionality is confirmed with covers in place.

- Keyboard Adjustments: We ensure the perfect angle and responsive keystrokes.

- Ribbon and Tape Installation: New ribbons and correction tapes are fitted for immediate use.

- Carbon Copy Calibration: Print hammers are adjusted to handle multiple copies while retaining correctability.

- Key Button Testing: Each key is tested for smooth operation without repeats.

- Ribbon Mechanics: Lift height and feed are fine-tuned for perfect ribbon performance.

- Secure Packaging: Custom boxes and foam caps protect your typewriter during shipping.

Shop with Confidence at Typewriters.com

We invite you to explore our curated collection of typewriters, each promising a journey back to the era of tangible craftsmanship. With Typewriters.com, type with assurance, type with legacy.

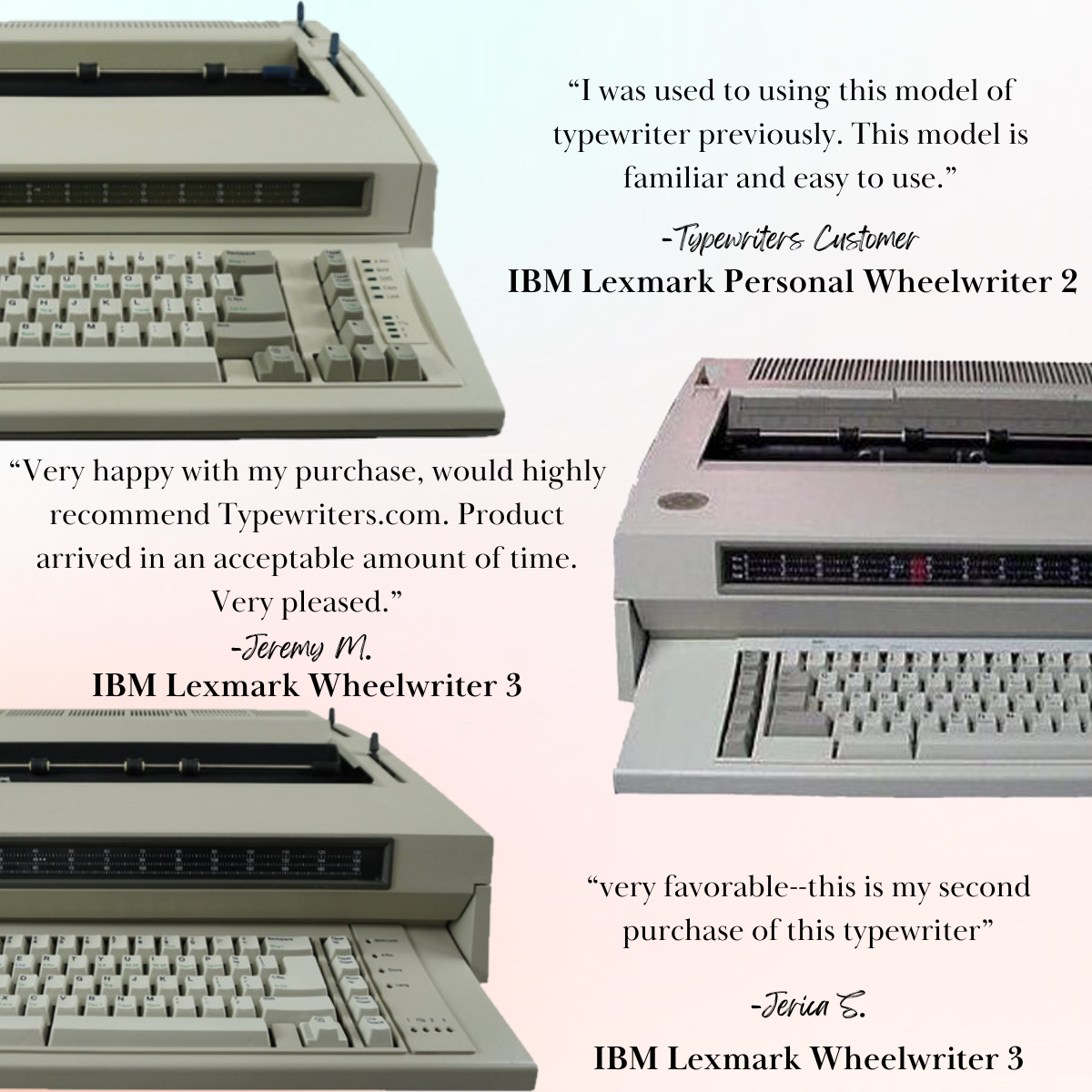

A Look At What Others Think About Our Wheelwriters!